1961 – the VTT-WB beliefs were born in this year.

This is how they have endured

SUCCESSIVE GOVERNMENTS FORGOT WHERE THE INDUSTRIAL REVOLUTION STARTED. IT WAS FOOLISH TO GIVE UP OUR MACHINE TOOL INDUSTRY. IF MACHINE TOOLS DON’T MAKE IT THEY MAKE THE COMPONENTS OF THE MACHINES THAT DO MAKE IT – EVERYTHING!

In 1961 I was in my first term at Loughborough Colleges studying to be a PE and Modern Languages teacher. A serious rugby injury required surgery and was going to put me out of action for a year or more.

Rather than waste a year I went to work in my father’s fledgling 3 man machine tool rebuild company. This partnership was immediately successful and he persuaded me to stay because, in his words, “Advanced countries like the UK, the US, Europe will always need machine tools because they make everything you can see or touch”

I had a very successful, very rewarding early career. I turned our small family business into a very serious high value high ranking private UK machine tool engineering group and when I left in 1976 to set up my own company the success continued. That put me into the position in1989 to buy 50% of Wickman Bennett the UK No 1 and one of the best known machine tool companies world wide.

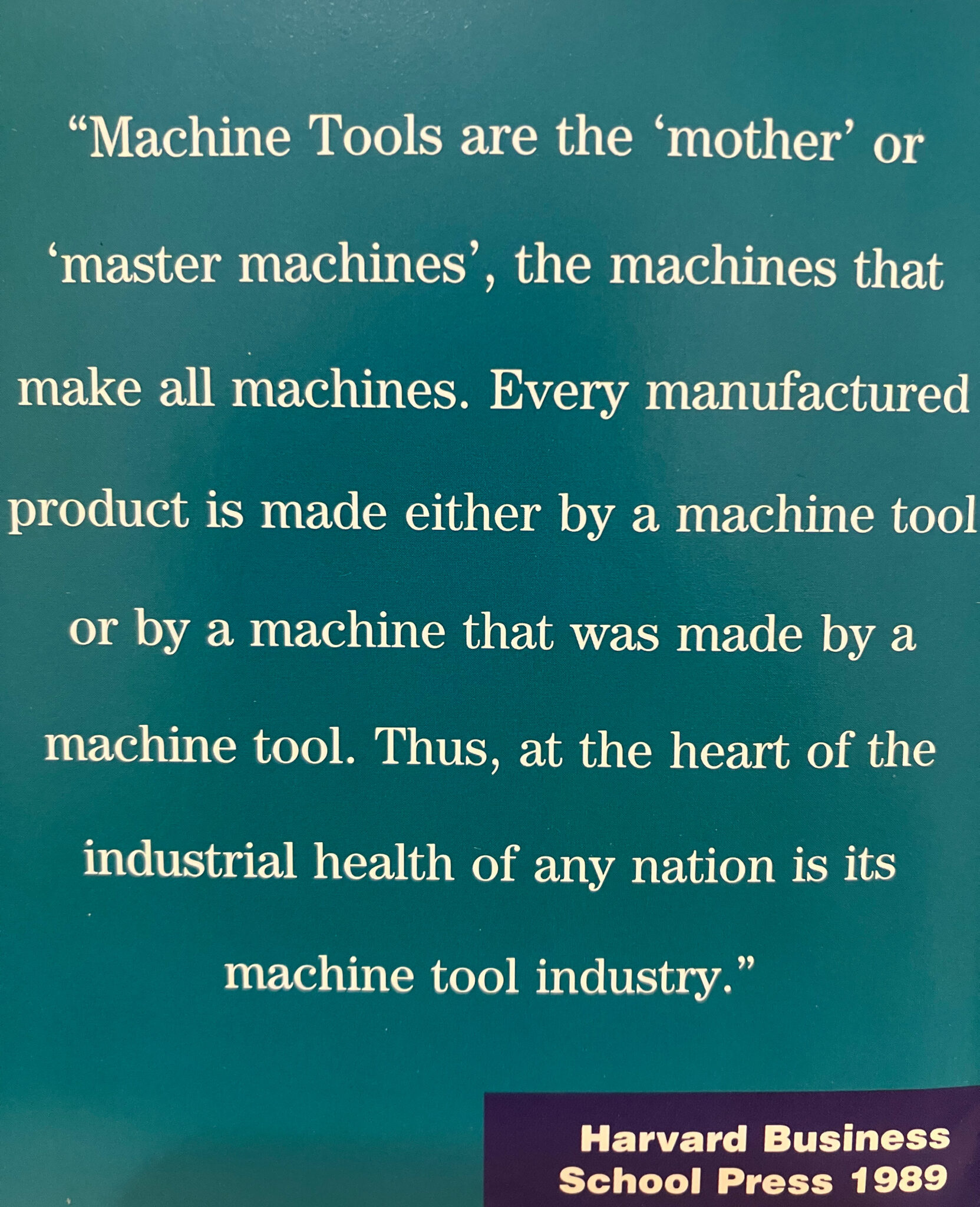

My life was very comfortable but I had seen Wickman and other UK machine tool companies sitting on their laurels, on their strong history. When the chance came to buy and run Wickman Bennett I knew I could turn the loss making company back into profit. I was undecided for a few days and then I read this Harvard press release – only one decision possible – go for it

Harvard are saying exactly what my father had said all those years ago. Back in the 1960’s I had taken a part time Post Graduate Diploma course at Woolwich Polytechnic that was based on the Harvard MBA. I had a lot of respect for and faith in Harvard and MIT.

This report totally convinced me – do it!. So I went forward and bought Wickman Bennett

I saw this Harvard statement published once again – in the MTTA 1996 report.

This was the year we built our first Millennium machine and won an MTTA design award

MTTA then was the Machine Tool Technologies Association.

Now, although at the same address, it is the MTA – the Manufacturing Technologies Association – no British machine tool builders left!

VTT-WB today

Despite not succeeding in keeping our new machine build I don’t regret we tried.

Machine tools are the mother of all manufacturing. We believe in machine tools and believe they should always be built with long life quality, not as 5 year disposables. Happily there are still engineering and manufacturing companies around the world that believe the same

And so we continue…………..

There are nearly 100 quality machines we built in Webster & Bennett, Wickman Bennett and Vertical Turning Technologies. These are in quality companies around the world. Our main focus now is to support these machines which were recognized as very sophisticated machine tools built to the very highest standard

Most of the high quality staff in our companies have retired. We have not been able to find fitters or sub contractors with our care and quality standard to replace them. So we are a small specialist company – whatever we do it will be with traditional quality or better

VTT-WB is small, but very effective. The development of Petr Gabrhelik, over the past 20 years has made it possible. This is how

In 2000 I went to Czech Republic to kick start the modernisation of a 2000 people machine tool company with huge potential. It was there I met a young electrical design engineer, Petr Gabrhelik, who was responsible for the design and assembly of electrics and electronics for one of the major contracts, building 40-50 machining centres every month for Okuma America. In 2004 Petr came to Warwick to take on the same responsibilities for Webster & Bennett.

In Warwick his responsibilities rapidly expanded. During the build, installation and commissioning of the high tech machines we built for some of the best known engineering companies in numerous countries he learned to cover every technical requirement, electrical. CNC and mechanical.

He is the best multi-task machine tool design and build engineer I have ever met. A bonus is that he is a very fit international standard Dragon Boat Racer. His fitness and agility help him to progress service, rebuild and assembly build at amazing speed!

This is why I have such a poor opinion of our government leaders and politicians in general

During my 60+ years in business I only met one politician, Norman Tebbit, who understood the damage caused by deindustrialisation.

People who liked working with their hands now have few opportunities to work in a precision environment that boosts their self esteem. When I was in my first 20 years in business the machine tool industry along with the automotive industry, British Steel, aeroplane manufacturers, aero engine manufacturers, serious defence product manufacturers, the power generation industry manufacturers and more and more provided hundreds of thousands of quality jobs for precision engineers and apprentices.

The UK could manufacture almost everything we need. Most of those manufacturing facilities have disappeared as the idiot politicians followed their leaders who promoted deindustrialisation. They do not understand that if you don’t make it you have to buy it. From the country’s viewpoint where does that money come from? Do the people who lost their satisfying and fairly well paid jobs now have enough income to buy quality good as we used to make them in the UK? No, hence the market opened up for cheap goods and the explosion of warehouses alongside the motorways to house and distribute them

Recently we have made several trips up and down the M6 and the M1. Huge warehouses, one after the other, alongside the motorways. Very depressing. If even 50% of the goods inside these warehouses was made in the UK we could have full employment of satisfying jobs, people back in more skilled jobs earning enough to buy better quality products.

Those who believe de-industrialisation is a greenhouse gas benefit are fooling themselves. Moving manufacturing to Asia has multiplied several times the greenhouse gas cost of each product made there and shipped here in huge pollution belching freighters. Steel is made in new, yes new! coal fired plants and the huge increase in the amount of power required by manufacturing facilities is provided by new coal fed power stations

Download History Power Point

History brochures

Exeter Machine Tools (London) 1977 (276kb)

Exeter – Clyde Valley – Central machine tool group (1.5mb)

Exeter – K.E.N.T 1982 (520kb)

Exeter Machine Tools 1982 (1.4mb)

Timex-Muller Machines 1983 (2mb)

Exeter – huge machines 1984 (426kb)

Exeter Machine Tools 1984 (912kb)

Oerlikon-Muller Machines 1984 (476kb)

Exeter machine tools 1985 (1.6mb)

Exeter Machine Tools 1985 (492kb)

CNC Lathes – Exeter Machine Tools – Stock List (1.4mb)

CNC Lathes in Action (276kb)

CNC Lathes in Action (276kb)

Machinery and production engineering (588kb)

Wickman Exeter 1986 (708kb)

Wickman Exeter 1986 (2) (976kb)

Wickman Exeter 1987 (764kb)

Wickman Exeter – CNC 1987 (600kb)

Wickman Exeter – High Tech 1987 (520kb)

Wickman 52-200 Series (560kb)

Wickman 76-250 CNC Turning Centres (268kb)

Wickman 26-130 KIS (288kb)

Wickman 26-130 SP (590kb)

Wickman Bennett Selection 1990 (453kb)

Wickman Multispindle autos 1990 (1.6mb)

Wickman Multiflex CNC 1990 (548kb)

Wickman Bennett vertical lathes 1990 (994kb)

Wickman in Production 1991 (1.10mb)

Wickman 1992 disaster (2mb)

The Future – 3 Vital Ingredients 1993 (658kb)

‘T’ Series Flexidrive 1995 (299kb)

‘TX’ Turret Lathes 1993 (342kb)

1995 (708kb)

India 1998 (354kb)

Millennium 1996(1.33mb)

Millennium Press Feature 1996(340kb)

News Bulletin 1994(594kb)

News Bulletin 1997(762kb)

The Millennium range 1999 (486kb)

French, Italian and German brochures (1.09mb)

Machine tool trading rebuild history brochures 1961- 1989

K.E.N.T. Machinery Group (21mb)

Exeter Machine Tools (London) 1977 (276kb)

Exeter – Clyde Valley – Central machine tool group (1.5mb)

Exeter – K.E.N.T 1982 (520kb)

Exeter Machine Tools 1982 (1.4mb)

Timex-Muller Machines 1983 (2mb)

Exeter – huge machines 1984 (426kb)

Exeter Machine Tools 1984 (912kb)

Oerlikon-Muller Machines 1984 (476kb)

Exeter machine tools 1985 (1.6mb)

Exeter Machine Tools 1985 (492kb)

CNC Lathes – Exeter Machine Tools – Stock List (1.4mb)

CNC Lathes in Action (276kb)

Machinery and production engineering (588kb)

Wickman Exeter 1986 (708kb)

Wickman Exeter 1986 (2) (976kb)

Wickman Exeter 1987 (764kb)

Wickman Exeter – CNC 1987 (600kb)

Wickman Exeter – High Tech 1987 (520kb)

Wickman Bennett – The Banner 1987 (432kb)

Wickman 1989 -1992

Wickman 52-200 Series (560kb)

Wickman 76-250 CNC Turning Centres (268kb)

Wickman 26-130 KIS (288kb)

Wickman 26-130 SP (590kb)

Wickman Bennett Selection 1990 (453kb)

Wickman Multispindle autos 1990 (1.6mb)

Wickman Multiflex CNC 1990 (548kb)

Wickman Bennett vertical lathes 1990 (994kb)

Wickman in Production 1991 (1.10mb)

Wickman 1992 disaster (2mb)

Webster & Bennett 1993 – 2010

The Future – 3 Vital Ingredients 1993 (658kb)

‘T’ Series Flexidrive 1995 (299kb)

‘TX’ Turret Lathes 1993 (342kb)

1995 (708kb)

India 1998 (354kb)

Millennium 1996(1.33mb)

Millennium Press Feature 1996(340kb)

News Bulletin 1994(594kb)

News Bulletin 1997(762kb)

The Millennium range 1999 (486kb)

French, Italian and German brochures (1.09mb)