Factory: Bay 7 BSA Tools Ltd Mackadown Lane Birmingham B33 0LE.

Machine Tools – vertical turning specialists

Sales : Service : Development : Modernisation

Contacts: Iain Exeter 07808 789597 iain@vtt-wb.com

Petr Gabrhelik 07808 789598 peter@vtt-wb.com

VTT-WB Ltd. What is in the name?

VTT – Vertical Turning Technologies – that’s our speciality. WB tells you why

WB – Webster & Benntt and Wickman Bennett – we designed and built all the new models since 1993

We specialise in service support and refurbishing the Webster and Bennett Vertical Turning Centers that we designed and built between 1993 and 2010 – the Millennium, Evolution, Revelation and Aeroturn VTCs and in providing the ManuPlus program for old W&B’s

For most machine tools we can offer cost effective breakdown and planned maintenance service – a single service engineer to look after CNC, electrics, mechanical and hydraulics. If you need this – contact iain@vtt-wb.com

DEINDUSTRIALISATION HAS BROUGHT THE UK TO ITS KNEES FINANCIALLY AND IS THE ROOT CAUSE OF MOST OTHER PROBLEMS

Click here TO UNDERSTAND THAT STATEMENT. MORE THAN HISTORY AND ‘TALK’ REINDUSTRIALISATION IS A DETAILED POLICY THAT SHOULD BE ACTIVATED BY THE OPPOSITION PARTIES BEFORE THIS INSANE GOVERNMENT BURIES THE UK

Why do we not build these machines new any more? Like many famous UK manufacturing companies we were victims to the imbecilic de-industrialisation policies of one UK government after the other during the past 45 years. Want to see see great achievements during these painful years- download the history pdf below.its 500mb but its worth it to see the full story.

The ManuPlus program is now in its 20th year

Old Webster & Bennetts become machines for the 2020’s Why waste the machines wonderful castings with over engineered spindle bearings. The speed gearboxes, the feed gearboxes, the brakes, the hydraulic controls, these were all wonderfully engineered parts from those times. Now we scrap them and supply the machines with clean, dry electric controls in full CNC or Manual-CNC configurations.

High quality at a very acceptable price

From the smallest Webster & Bennett 36” to the 144” Double column. We have developed a range of options to make these machines more productive.

Two 60year old examples shown herel

OPPORTUNITIES - from time to time we can offer these machines refurbished, modernised if necessary, always guaranteed

The MILLENNIUM is not only a very good looking powerful and precise vertical turning lathe

it has superb milling, drilling and grinding capabilities

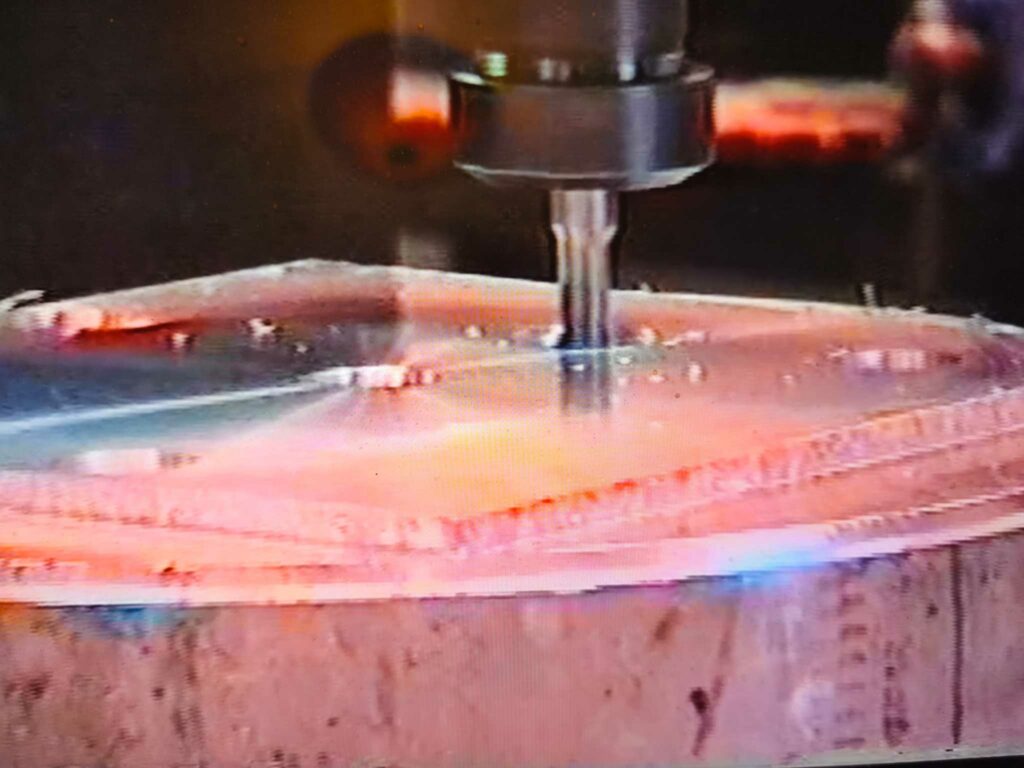

Turning a Trent800 engine casing

Angle PCD Drilling

makes tough chips

Square Milling

Oil and Gas heavy turning

Off Centre Thread Milling

Rotary Milling

Very Tough PCD Drilling

VTT-WB is currently preparing for sale the Millennium 3E-175/210 described below.

It will come with full 12 month warranty including PMP at 6 and 12 months

Webster & Bennett Millennium 3E- 175/210 High speed 3 Axis elevating crossrail CNC vertical turning lathe with Fanuc 18Ti CNC.

Powerful high speed Live Spindle and powerful and precise C axis control of chuck

The Millennium provides very high precision turning and versatile machining capability. Always precise, always powerful.

Features of this machine:-

– Involute chain drive for very high speeds, very low noise – a 36” diameter Timken cross roller bearing, the ultimate bearing

– All steel 1750mm dia. 4 jaw chuck for high speeds. Maximum loading 15,000kgs. – A servo powered C axis control that provides backlash free C axis movement – high power and high accuracy

– 200mm square forged steel ram – high accuracy heavy cutting when required and incorporating a 15KW ISO 50taper live spindle providing speeds 20 to 3000rpm. Look at the films to see rotary contour milling, angle milling and drilling – Automatic pick up of turning tools, live tools and attachments from the 18 pocket tool magazine

– Raise and lower crossrail – high precision latching and clamping at 200mm pitches – flexibility without loss of accuracy

Table Diameter 1750mm Maximum Turning Diameter. 2100mm

Table Speed Range (infinitely variable) 1 – 400 rpm Minimum at full power 24rpm

Main Drive 37 kw Maximum Table Torque 17800 Nm

Maximum Cutting Force 50kN Feed Force for Turning – ‘X’ axis 30kN

Maximum cutting height above table 1200mm Vertical Travel of Cross Rail 600mm

Ram – Z Axis Stroke 1000 mm Feed Force ‘Z’ 45 kN

Axis feed rates 0 – 5000 mm/min Rapid traverse speed 10000 mm/min

Positional Accuracy ‘X’ & ‘Z’ + 0.0075 / 1000 mm Repeatability 0.005mm/1000mm

C axis speeds

Toolchanger magazine max load 700kg Max individual tool weight/length 53kg/450mm

Approximate machine weight 40,000gs

In process of full servicing, full alignments and functions testing and new guarding being fitted. 12 months warranty and 2 planned maintenance visits – after 6 months and after 12 months

Dismantled and loaded to transport at our works close to Birmingham Airport. £315,000

We built these machines new and are very experienced moving, installing, commissioning and fully supporting them

We will be happy to quote for whatever assistance the purchaser requires

Installation cost depends on customers location and lifting facilities. Budget £12,000 plus Versalift costs (if no overhead crane )

Machines in the Millennium range weigh 2.5 to 3 times the weight of similar capacity machines that made Webster & Bennett the world leader in the last century. The Millennium took W&B to a new level that took the company back to a world leading position

As with all Millenniums this machine has the wonderful base structure and table drive design that makes all the production wishes possible – the highest accuracy and the highest chip removal https://www.vtt-wb.com/

When this machine is delivered to the customer it will have been fully serviced and refurbished to ensure those qualities are ready for you to use turning, pcd drilling, rotary contour milling, angle drilling, grinding – look at the film!

There are few machines of this quality, strength and versatility. If you find one it will probably cost several times more

For more visual information of what the Millennium range has achieved for world leading companies and to see what it can do for you take a look at the Millennium films https://www.vtt-wb.com/millennium

another example of versatile milling with the Millennium live spindle and powerful, precise C axis

A KARUSSELL (BRITISH) 3600MM 2 AXIS CNC VERTICAL LATHE

The 2015 Karussell with Siemens 802D CNC. If you want this capacity this is a special opportunity

Why we no longer design and build new machines.

Successive governments destroyed UK manufacturing with the deranged policy to deindustrialize the UK that took off 40 years ago. They did not understand that machine tools are the mother of all manufacturing. My ranting is public on my web site https://www.age-fit.com/

We designed and built new Millennium machines that were producing very important defence and aerospace components for some of the world’s best companies We can no longer build these machines new in the UK. That is a very sad story because the whole home grown UK machine tool industry was substantially destroyed in the 1980/90’s by government incompetence and ministerial lies. A disgraceful performance by our government

VTT-WB continues the support for the Millennium and the other models we designed and built – Aeroturn. Evolution, Revelation and ManuPlus

With loss of our millions of working capital over the ‘machine tools for Iraq’ we were subsequently at the mercy of funders. Twice we took Webster & Bennett back to a recognized world class position but twice success backfired on us. We have an exceptional range of designs, mostly well proven but the capital is not available for this industry – shame because I would have no trouble funding a coffee shop

Designs for sale – Manufacturing Partners needed – We are looking for partners to manufacture these machines.

The Millennium and Revelation require a large machine tool designer and builder.

The Aeroturn was designed to be built easily by a small company.

The Evolution and ManuPlus are perfect for a small company located in one of the countries where there are many existing Webster & Bennett installations

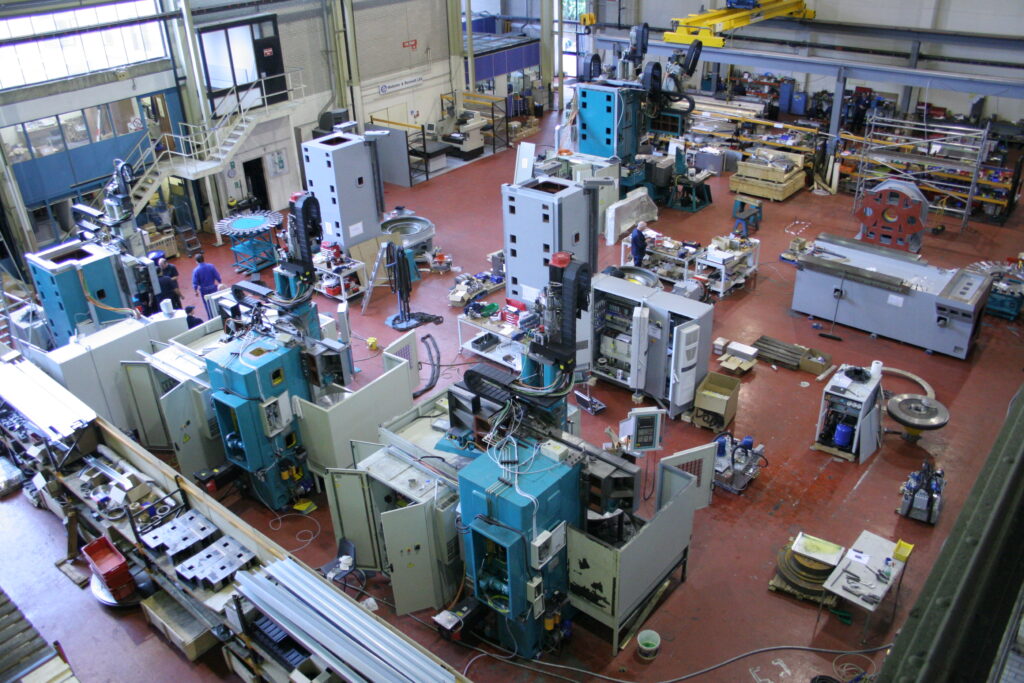

All these machines were built in the Warwick facility between 2004 and 2008. 1500sq.m. of machine tool build efficiency – 17 machines in one year

This film shows the first Millennium we refurbished 6 years ago. It is a 3E-125/150 VTC, a sister to the smaller Millennium currently being refurbished. The first machine continues to turn and machine extremely precise and important defence components

An introduction to a very sad situation – for decades we have been governed by people who do not understand these simple things

If you do not make it you have to buy it. The UK used to make everything. Now we have to buy it

Machine tools are the mother of all manufacturing. They make the machines that make everything. 40 years ago the UK had an internationally recognized very strong machine tool industry that got into trouble because weak management could not work with the unions, not all were politically motivated, and succumbed to the nonsenses of one incompetent government decision after another that promoted de-industrialisation that has destroyed our abundance of skilled engineers. I experienced all the expectations of the 1960’s, then witnessed the negative years that followed. I don’t hold back in criticizing those responsible. Look at age-fit.com

What Harvard say here is so true. It is so obvious.

Before the Industrial Revolution there were hand tools and most components were made in wood. Industrialisation was initially benefitting agriculture and textiles but not so much transport and steam/power generation where metal parts would increase operating specifications and the life of the vehicles and machines used in transport and power. As different machine tools were invented and developed interchangeability of parts, a huge benefit, became possible.

During the second half of the 19th century machine tools became the largest industrial sector in the USA. The UK machine tool industry was also developing fast producing machines whose names would be amongst the most important world wide throughout most of the 20th century – Herbert, Wickman, Webster & Bennett all from Coventry, together with BSA in Birmingham. Smaller companies in these two great cities developed many specialized machine tools

The machine tool industry in the UK and the USA were major contributors to our success in the World Wars. Since 1981 our ability to manufacture weapons and armoured vehicles has reduced with the decades of de-industrialisation policy. The UK manufacturing capacity that remains is almost full of machine tools built overseas, many in countries that we have been to war with or had a poor relationship with. If we fall out with them where do we get spare parts or replacement machine tools? Cars, airplanes, tanks, ships, railways, power stations – made them all but now we spend hundreds of billions for people to make them for us. Senseless

The effects of these deindustrializing policies on Greenhouse gas effect? Not what most people think! They have their heads in the sand.

Want to read more or argue with me – I invite you to this link age-fit.com/govt/idiocy

The 1992 document shows the quality of our manufacturing facility in 1992 about to be destroyed.

Our destruction was just one of many, as result of Government ineptitude.

In the history document you can see more photographic examples of our achievements.

We are looking for manufacturing partners for these machines. The sales potential is world wide

If you are interested please email iain@vtt-wb.com and I’ll send you the information package

THE MILLENNIUM

A range of vertical turning centres. These were purchased by world leading companies because of their innovations and high quality performance. A design that has proven to hold its world class performance. High speed, high power, super precision turning , contour milling and grinding.

Click on the photo to see film and photos of the Millennium in build and in action

We specialize in supporting and modernising the Webster and Bennett Vertical turning centers that we originally designed and built between 1993 and 2010. We can support most machine tools

Contact us for any machine tool support of all quality CNC machines

THE EVOLUTION

machines are built using the wonderful over engineered basic structure of the W&B 36, 48 and 72 manual machines.

Result – a new machine for turning, grinding and PCD drilling – 12kw. Turning diameters to 2100mm

Click on the photo to see film and detail photos of The Evolution in build and in action

Since 2004 we have given older Webster and Bennett vertical borers a new life and a new 2020’s specification chosen from the range of ManuPlus specifications

THE REVELATION.

A range of super heavy vertical turning centres for turning, grinding and contour milling. Capacities up to 5000mm dia.

Very innovative tooling developments and robot loading

Click the photo to see film and photos of the machines we built

Machine tool rebuilding since 1961

Webster & Bennett vertical turning specialization since 1986

We can provide high quality service support for all quality machine tools. Take a look at our history brochures

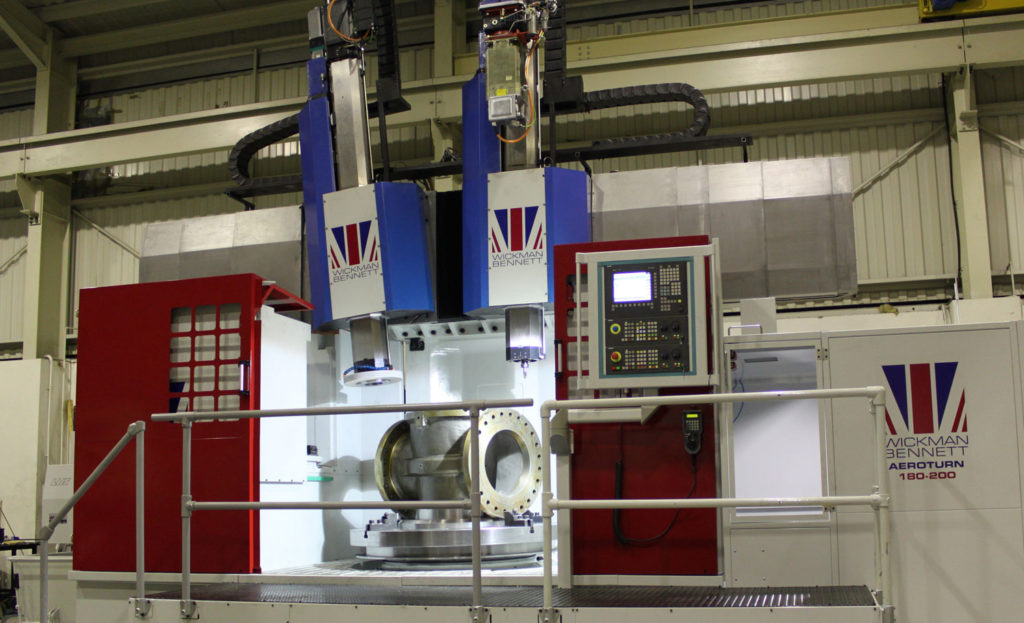

The Aeroturn CNC vertical turning centre

The last range of machines we built new in 2010.

Designed to offer a lighter duty machine than the Millennium. Even with linear guideways it proved to be a very powerful machine for precision turning, milling and grinding

Click the photo to see film and photos of the machines we built

We can provide high quality service support for all quality machine tools. Take a look at our history brochures

ManuPlus

ManuPlus – 15 to 50 tons of recycling in one machine

That is Green!

Webster & Bennett the best known vertical boring machines in the world

VTT-WB – specialists with the history to service, upgrade and modernize these great machines

VTT-WB – updating with qualities that made Britain a world leading machine tool designer/builder

VTT-WB ManuPlus program giving 50+ year old W&B machines a new outstanding 2020’s capability