The Millennium CNC Videos

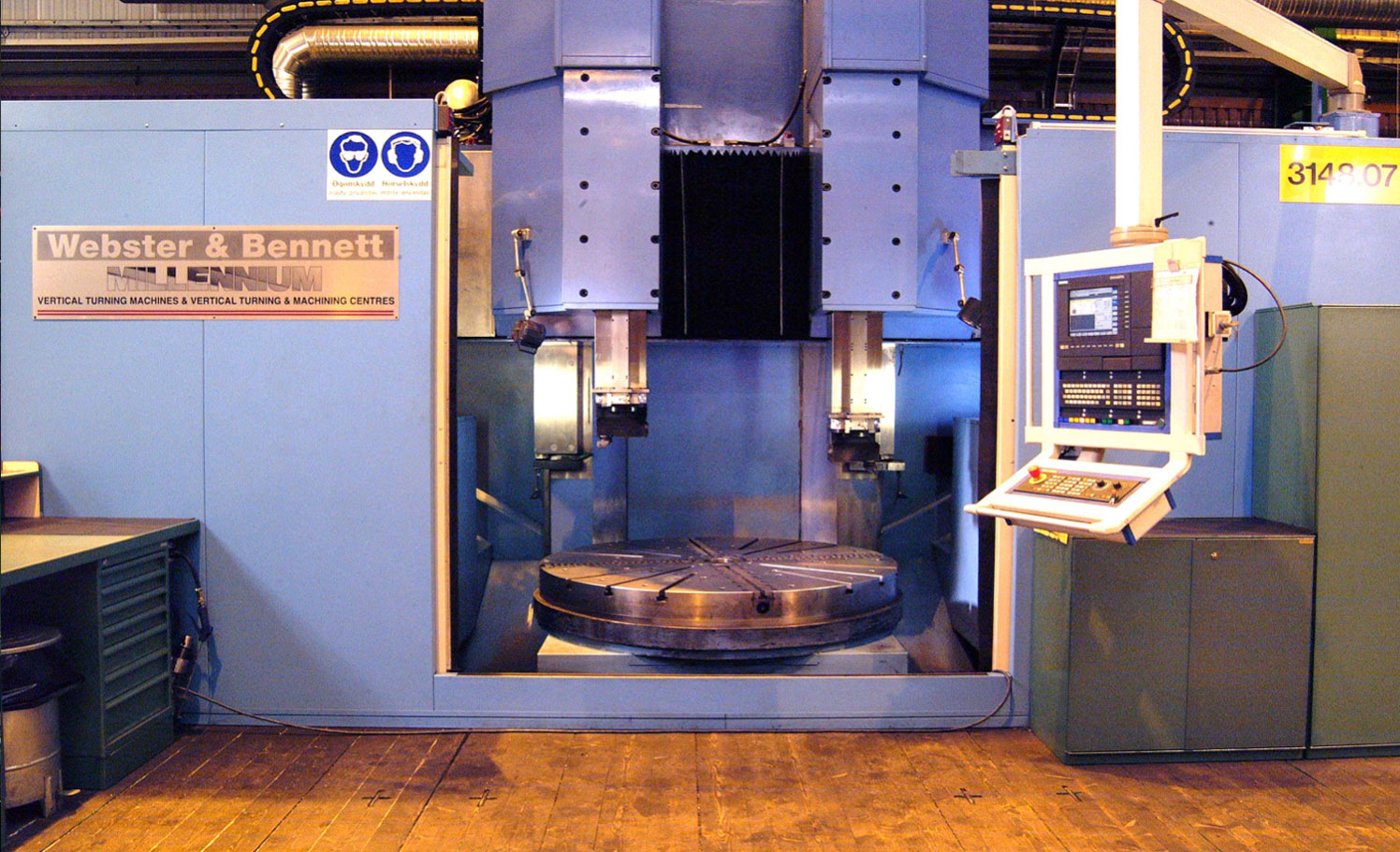

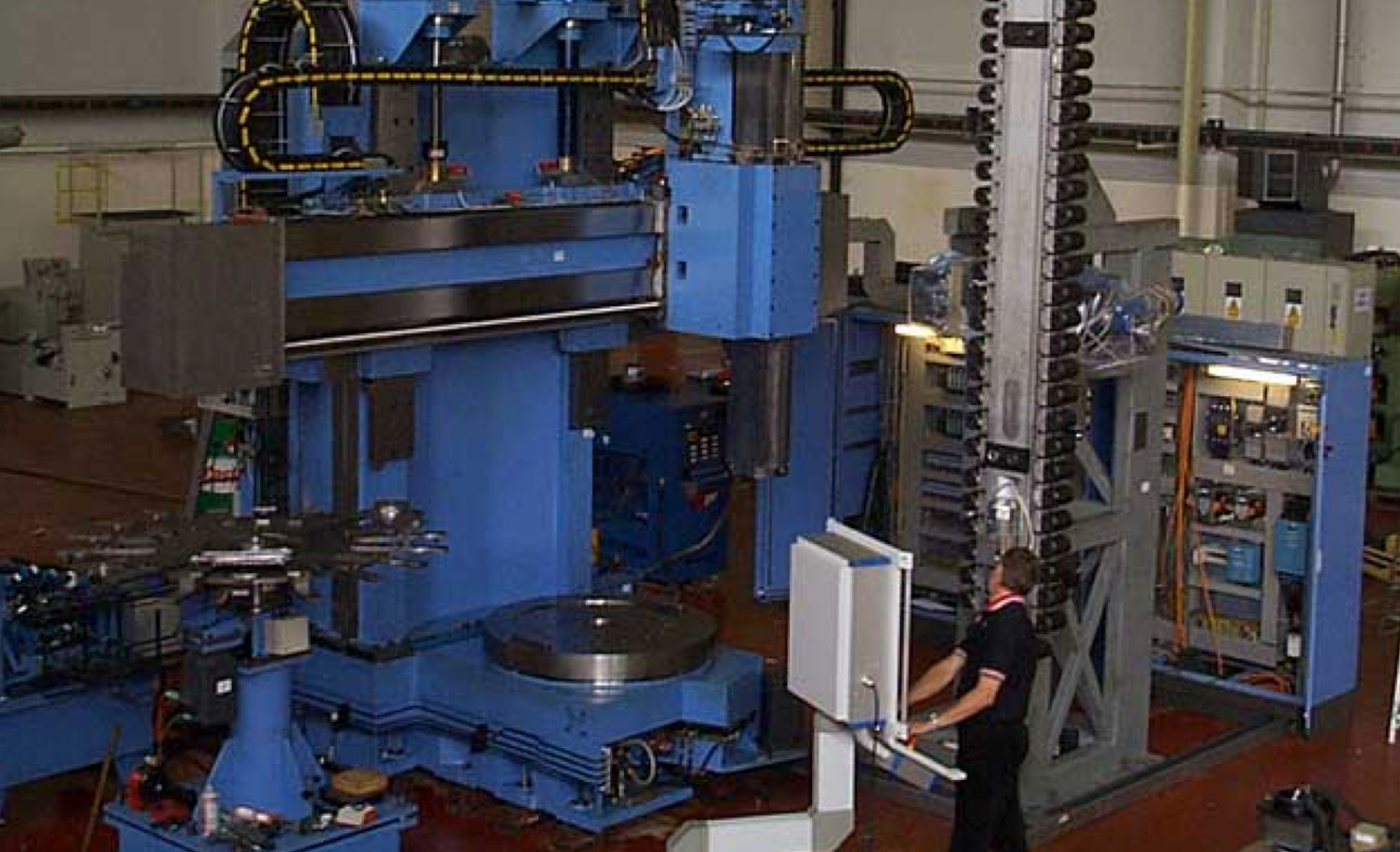

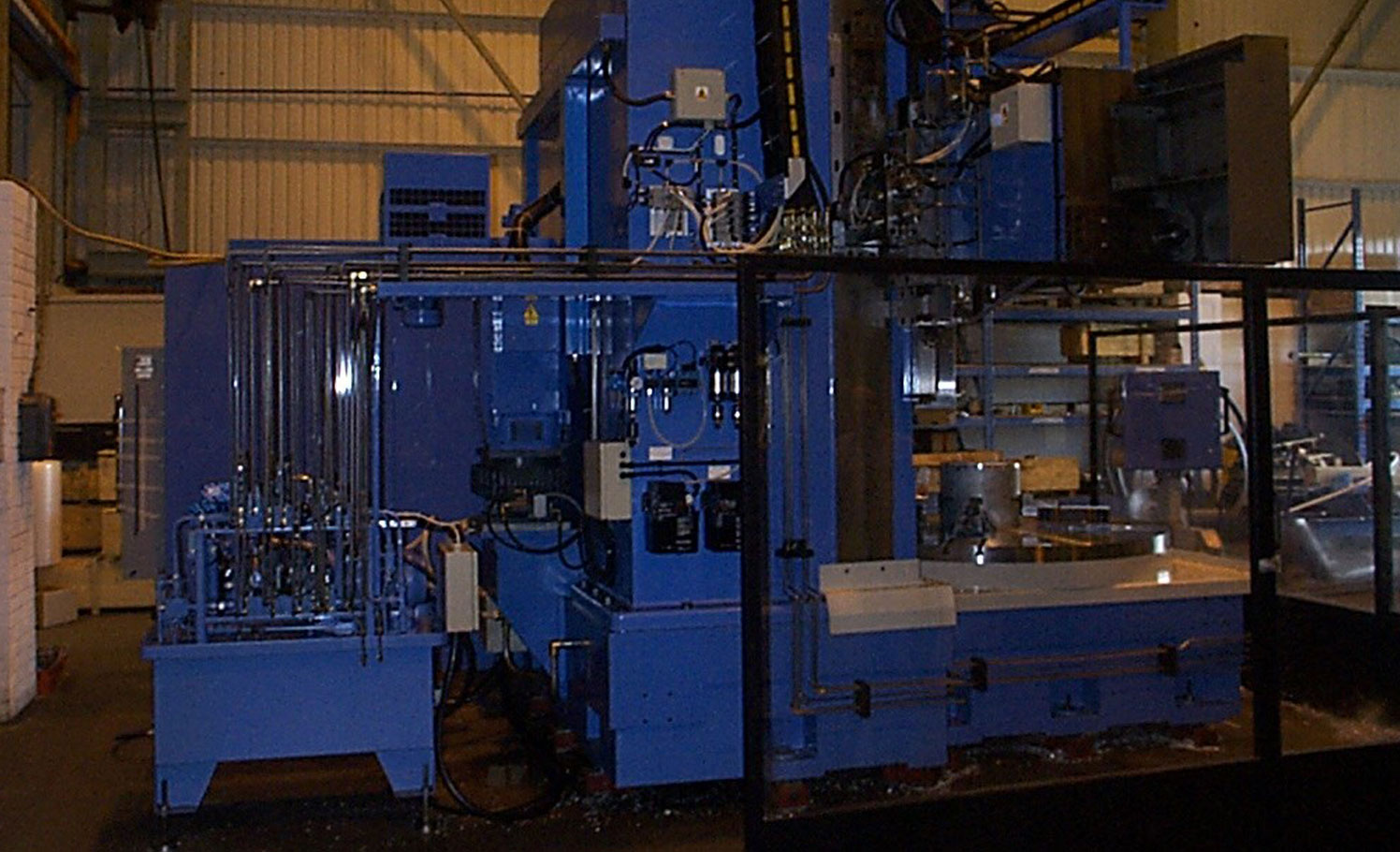

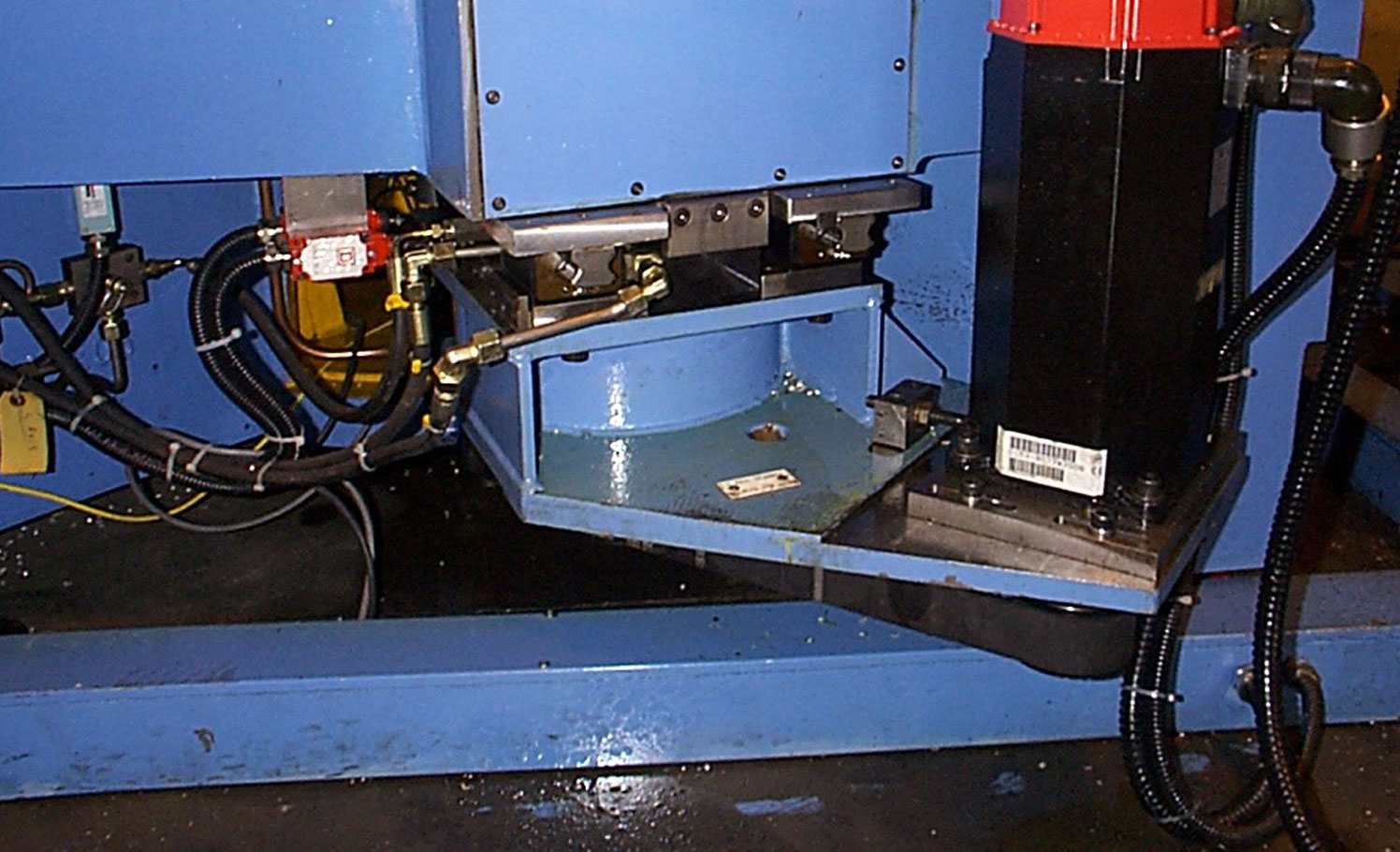

Webster & Bennett Millennium

3-120/150 vertical turning and milling centre with Siemens 840D CNC

Serviced and refurbished to work to original new machine tolerances. 12 months full guarantee

PRICE £295,000 installed and commissioned in your works subject to the extra costs of travel, accommodation, transport, rigging/lifting and duty.The price includes 12 months warranty of 96% uptime performance and a full PMP service at 6 months and 12 months, only cost being travel and accommodation

THIS MAY BE A ONE TIME OPPORTUNITY FOR YOU LOOK AT THE LINKS TO THE SHORT FILMS – THIS IS HIGH PERFORMANCE

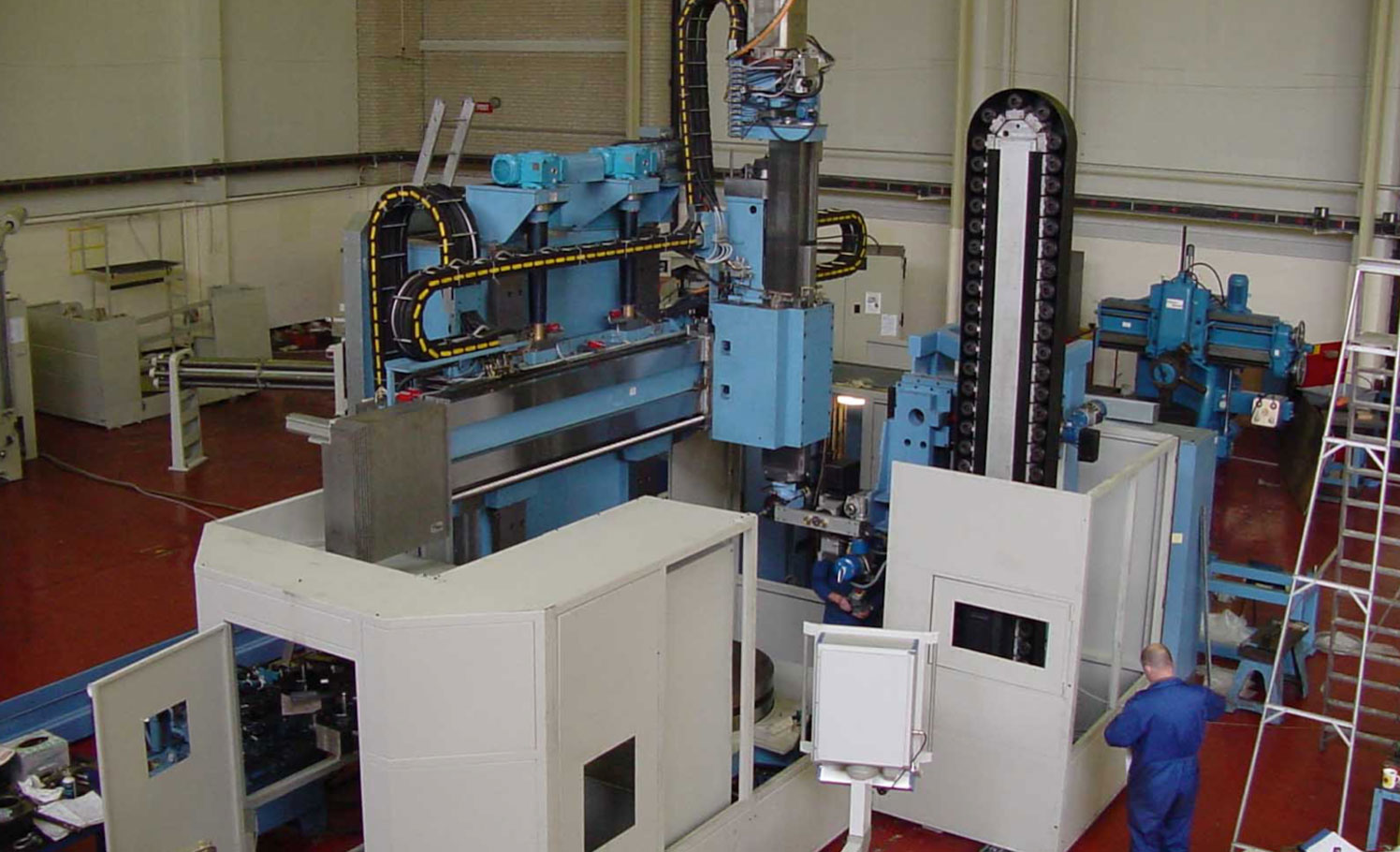

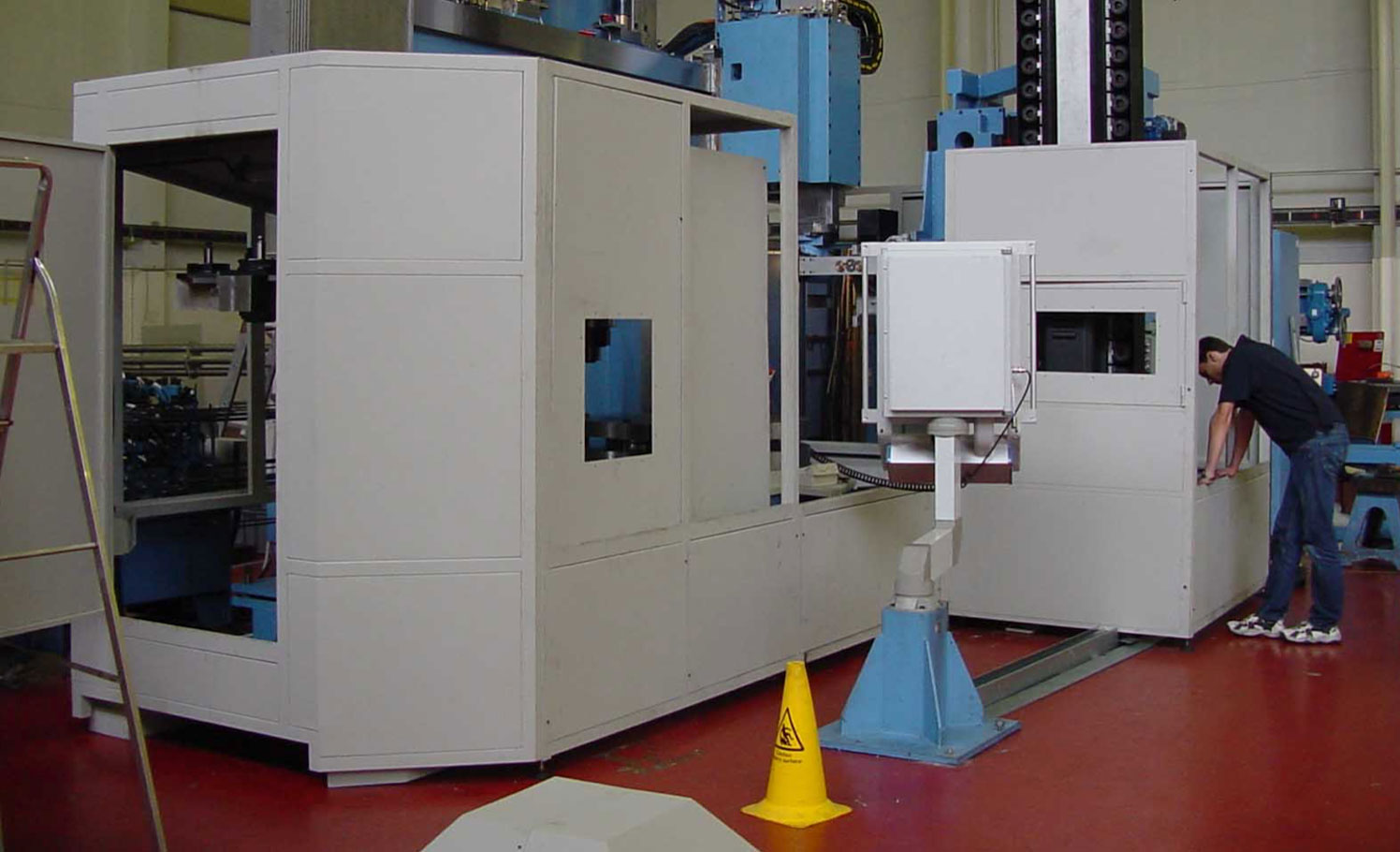

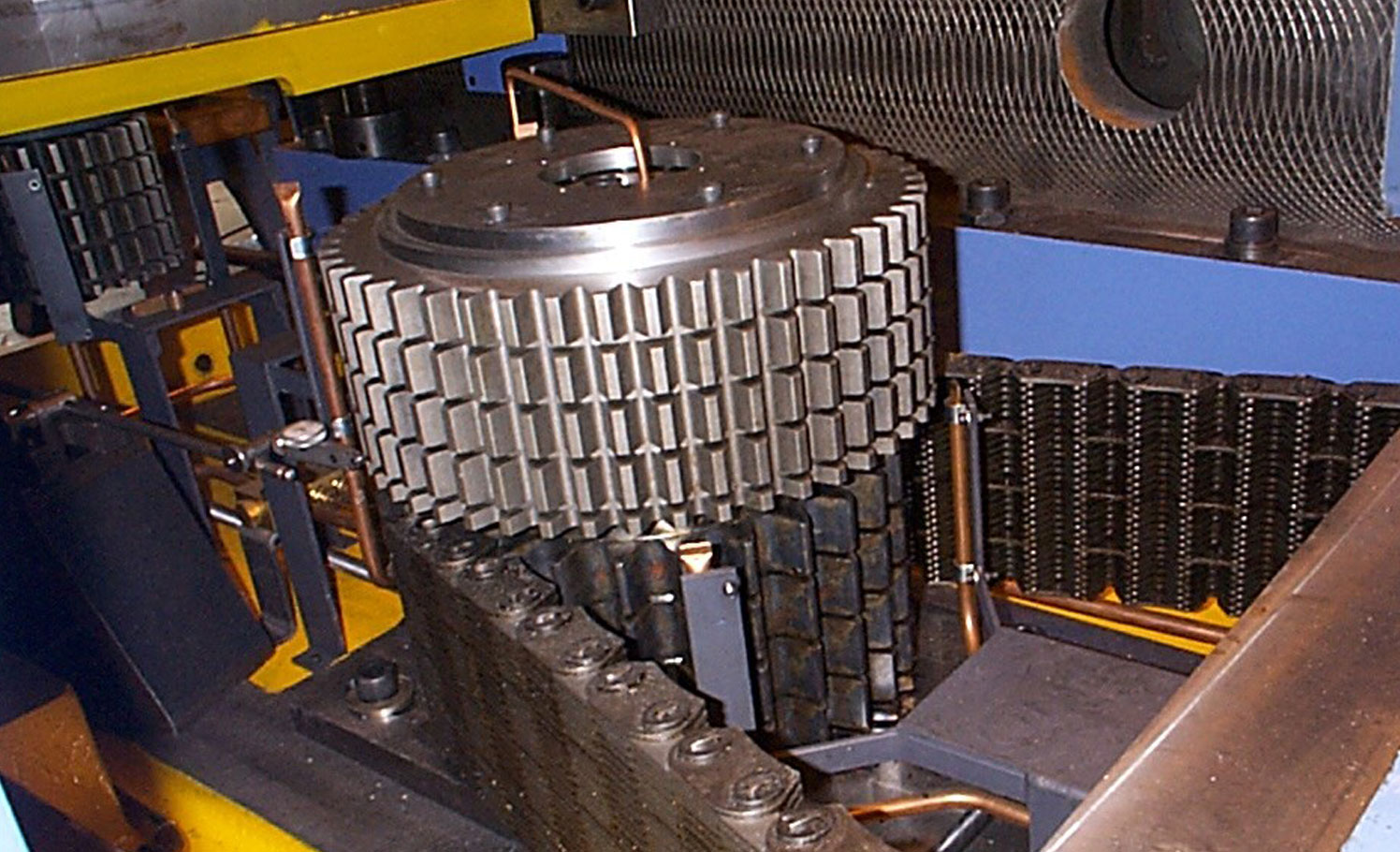

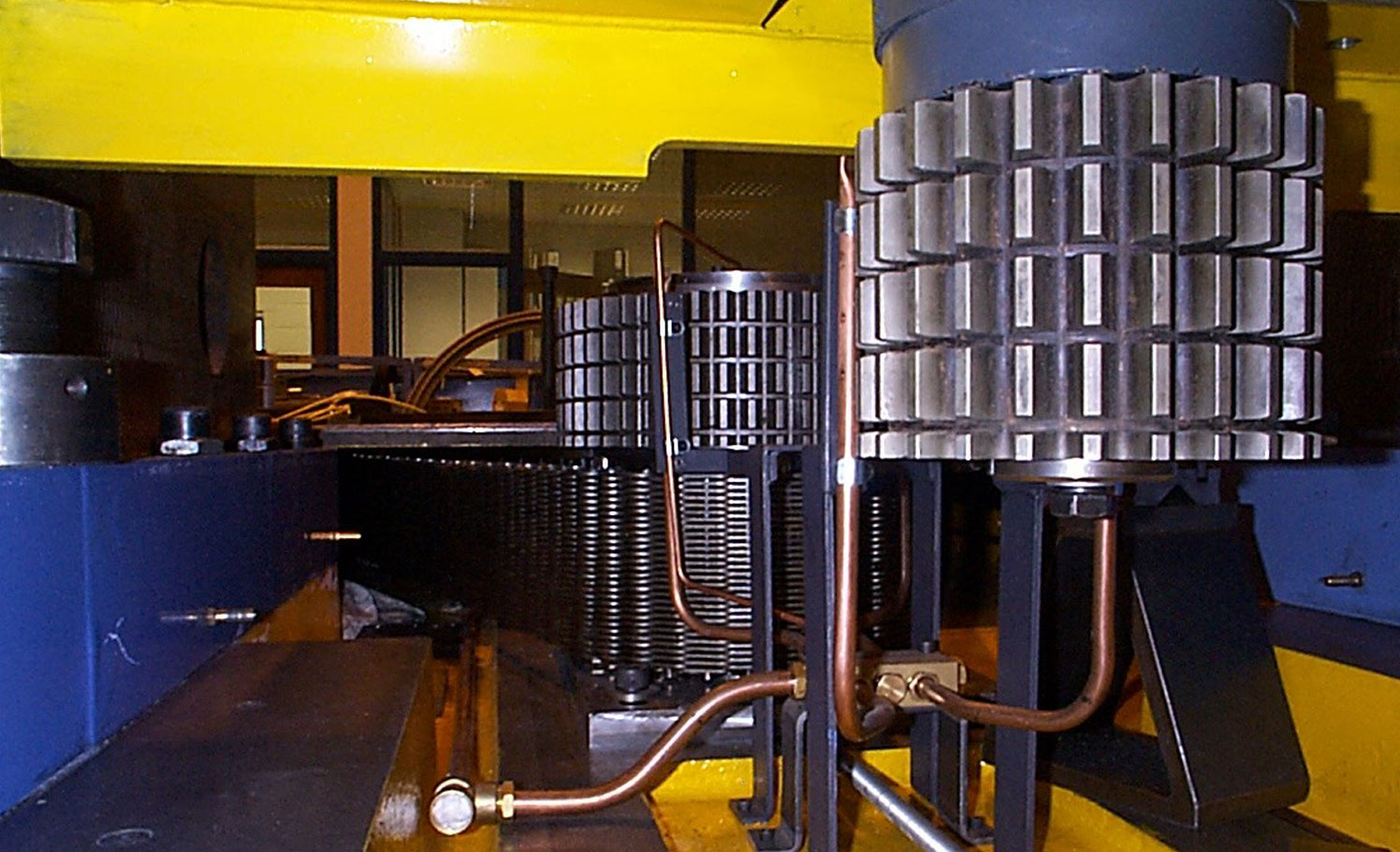

Webster & Bennett Millennium

2 axis CNC vertical turning lathe

model 3E 175/210 VTL

Fanuc 18Ti CNC

Machine available from existing users factory. Can be viewed and tested by arrangement

PRICE as seen and tested ex users factory £140,000, including dismantling and loading to transport