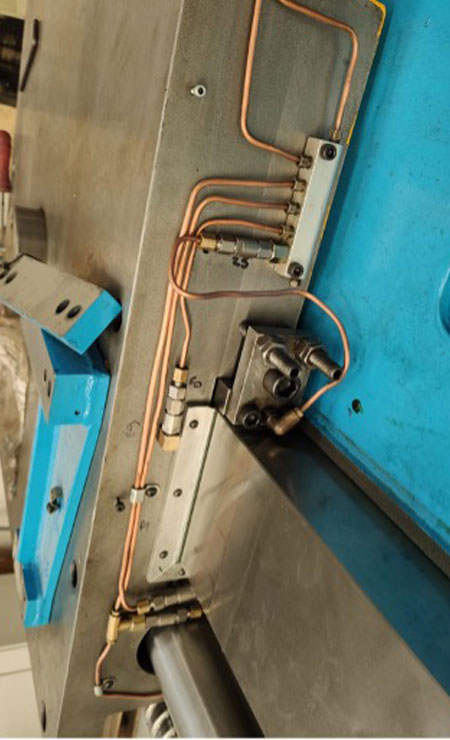

YOUR OPPORTUNITY TO BUY ONE OF THE FINEST MACHINE TOOLS EVER BUILT

WHEN THE MILLENNIUM VERTICAL TURNING CENTRES WERE INTRODUCED 20 YEARS AGO THEY WERE RECOGNISED AS WORLD LEADING MACHINES

THEIR SPECIFICATION, RELIABILITY AND PERFORMANCE CONTINUE TO BE RECOGNISED AS WORLD CLASS

THIS MAY BE A ONE TIME OPPORTUNITY FOR YOU LOOK AT THE LINKS TO THE SHORT FILMS – THIS IS HIGH PERFORMANCE

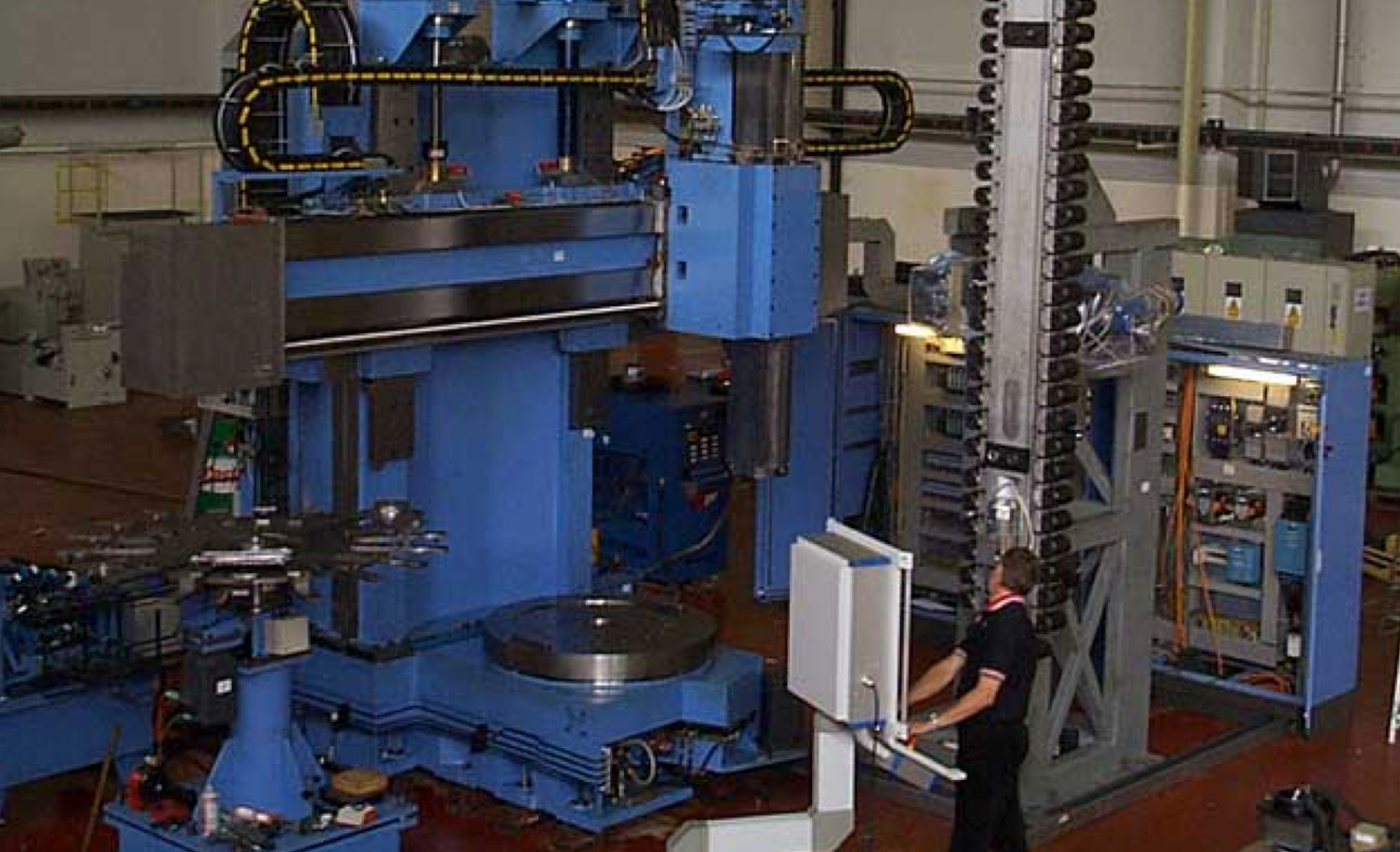

MILLENNIUM SERIES 4 - Model 180/200 high speed vertical turning and milling centre

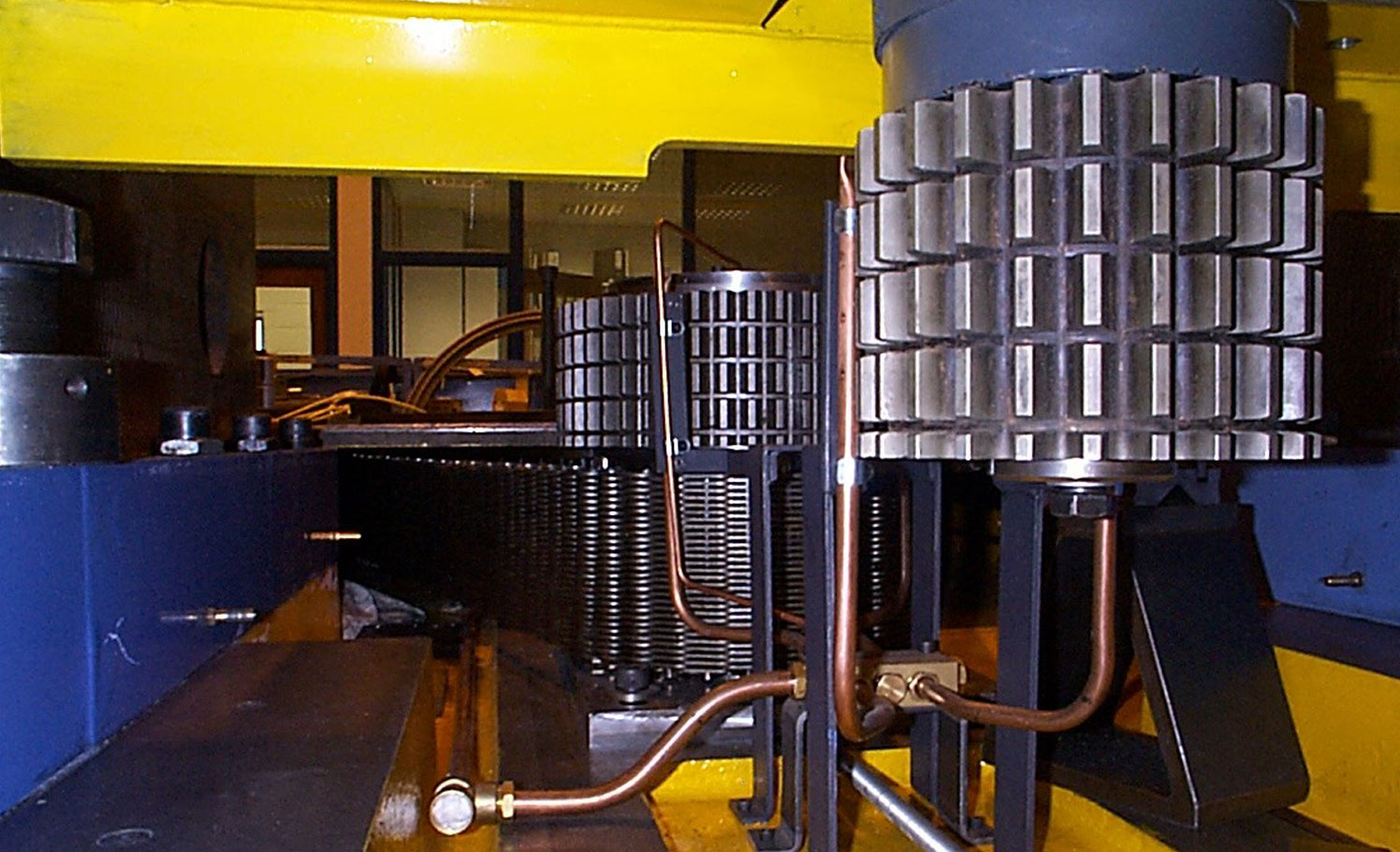

High speed turning plus a powerful live spindle and C axis for rotary milling and drilling. The long cross rail enables tool pick up from two 18 pocket tool magazines |

This machine has a very sophisticated specification with a tooling package of very high value. It was ordered to a specification to enable the manufacture of high precision large marine gears using an extensive range of angular drilling, tapping and milling heads. This tooling package was used in addition to the machine’s high precision turning capability to enable a one stop process, apart from gear cutting. The high quality turning capability eliminated bore grinding of the hub. The tooling package includes 5 adjustable angle Capto driven heads as seen in the film and below Two 18 pocket heavy duty tool magazines to incorporate 36 tools or attachments The original cost of this CAPTO tooling package was £139,000 |

This machine is available following the closure of a major company in the steel industry. The structural condition is very good, the guideways show minimal wear. Our new machine build experience and our servicing and rebuild experience of Millenniums enable us to refurbish this machine to a very high standard and offer it in very high quality, cost effective formats to suit the users requirement

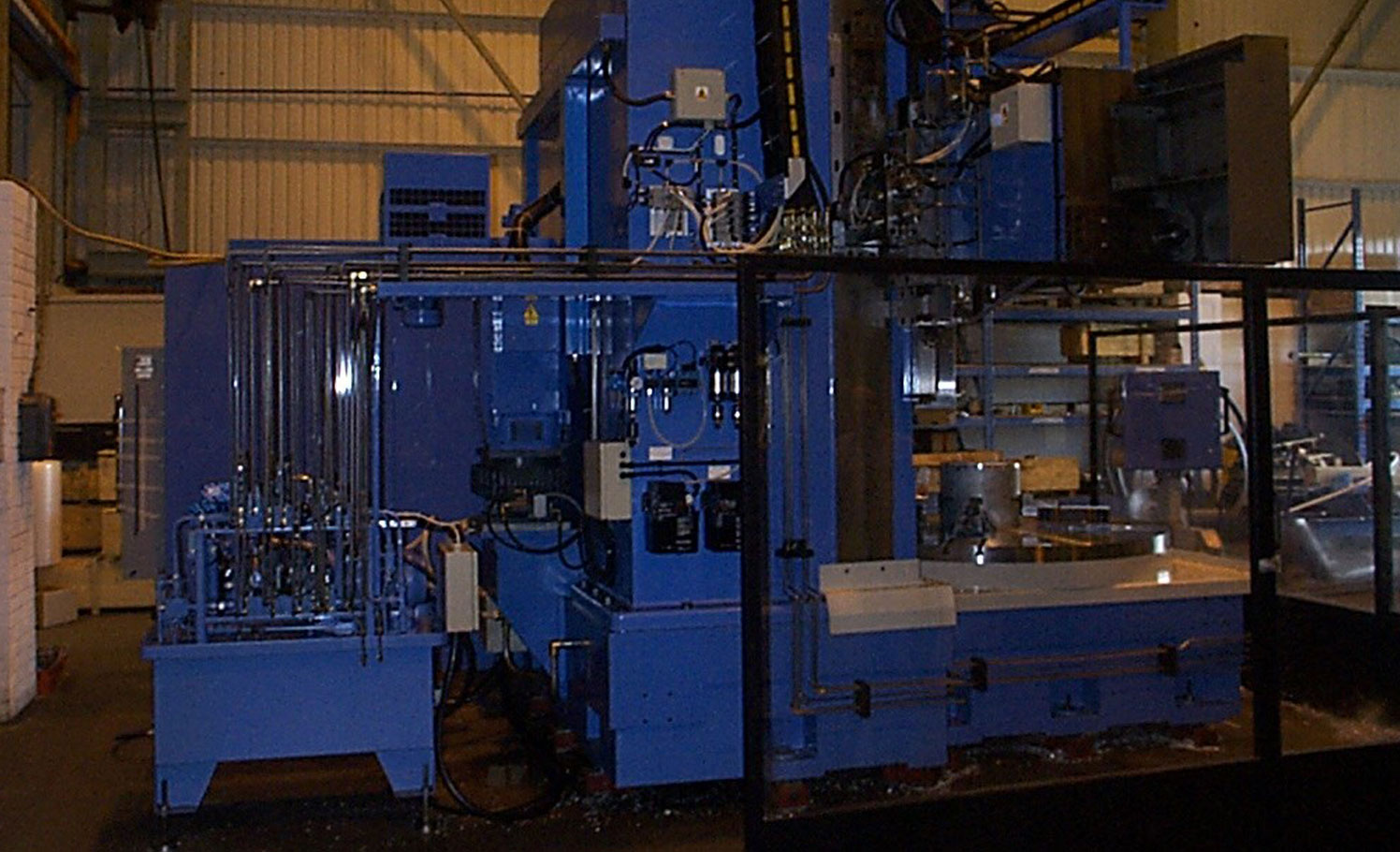

About the Millennium

When first introduced the Webster & Bennett Millennium range was immediately accepted as world leading series of vertical turning centres that were purchased by some of the best known world leading companies in the businesses of aero engine manufacture and repair, oil and gas components, gear drives, power generation, rail and defence rocket production

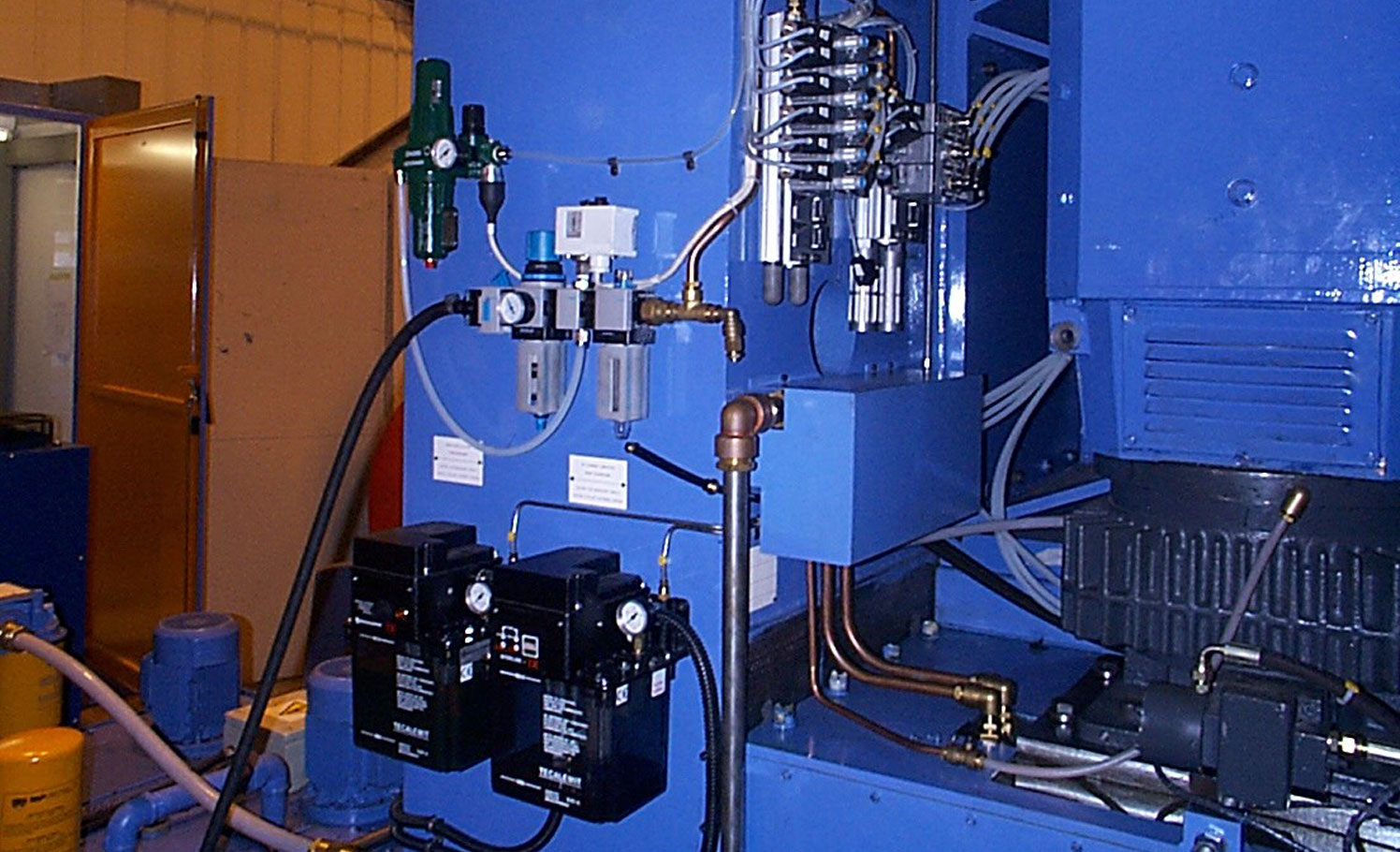

The Millennium is world class in its major structures and capabilities and it is a cost effective investment to refurbish the structures and modernise the CNC, electrics, hydraulics and pneumatics

The result will be a machine with basic structures of a higher standard than is found in most machine tools built today and this will be coupled with the latest available operating facilities If you can find the equivalent new machine today the cost will be several times more To see the whole Millennium range in action please take a look at this 6 minute film https://www.youtube.com/watch?v=8goOg-CrRS0&feature=emb_logo

|

Click here to see the features and capabilities of this specific machine on film

CAPACITIES and SPECIFICATION

4 Jaw steel chuck, ………………………………………………………………………………..1800mm

Maximum Turning Diameter………………………………………………………………… 2200mm

Maximum Swing ……………………………………………………………………………….….2200mm

Table Speed Range ………………………………………………………………………….1 – 440 rpm

Minimum Table Speed at Full Power ……………………………………………….……..29 rpm

Main Drive Motor ………………………Siemens 55kW AC (75kW on 40% duty cycle)

Maximum Cutting Force …………………………………………………………………………..50kN

Feed Force for Turning ‘X’ ………………………………………………………………………..30kN

Maximum Table Torque ……………………………………………………………………24556 Nm

Maximum Table Loading ……………………………………………………………..…….12,000 kg

Maximum Height under Cross Rail …………………………………………………….2000 mm

Minimum Height under Cross Rail ……………………………………………………..….600mm

Maximum Cutting Height above chuck face ………………………………………..1840 mm

Vertical Travel of Cross Rail …………………………………………………………………1400 mm

Cross Rail Precision Latching Increments ……………………………………….………200mm

Maximum Cross Rail Positioning Speed ………………………………………..1000mm/min

Full length X axis travel enables ram to pick up tools from both 18 tool ATC magazines

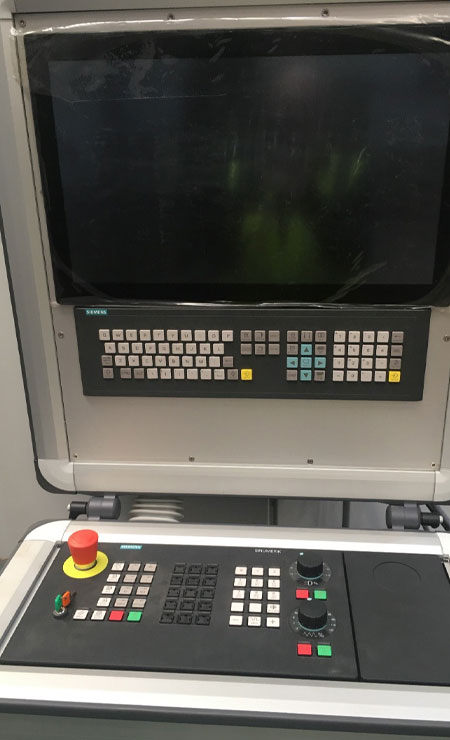

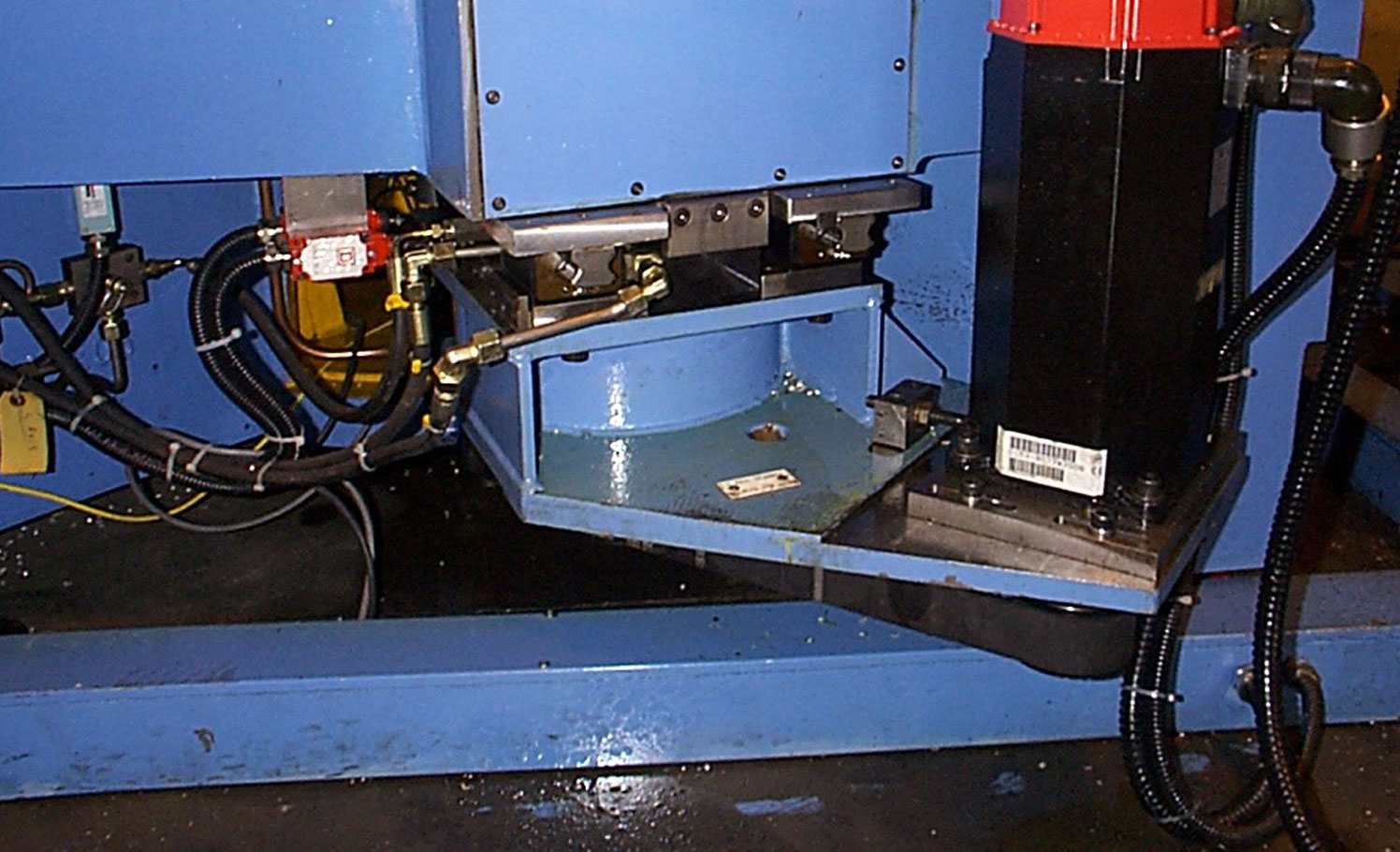

The Live spindle ram – Tool clamping – the hydraulic ram nose has 4 powerful pistons to locate and clamp all types of toolholders, tooling and attachments very precisely and very securely

Forged steel ram section …………………………………………………………… 250 x 250mm

Z Axis ram stroke.……………………………………………………………………..…………1500mm

Feed Force ‘Z’ ……………………………………………………………………………………………45 Kn

Ram Live Spindle Power…………………………………………………. 18.5kW (22kW at 50%)

Ram Live Spindle Speeds……………………………………………………………….… to 4000rpm

Live spindle taper………………………………………………..50 taper – DIN6987/ISO7338/1

C axis – for powerful rotary contour milling

- Accuracy………………………………………………………………..……… +/- 5 arc seconds

- Repeatability……………………………………………………………….+/- 2.5 arc seconds

- Table Speeds for rotary milling ………………………………………….…0.1 – 3.1rpm

- Torque ………………………………………………………………………………………6.25KNM

- Table Speeds for positioning – drilling, right angle milling etc.0.1 – 6.5rpm

X and Z Axis Feed rates …………………………………………………………….0 – 5000mm/min

X and Z Rapid traverse speed ………………………………………………………12000mm/min

Positional Accuracy X and Z axis…………………………………….…. +0.0075mm/1000mm

Repeatability …………………………………………………………….…………..0.005mm/1000mm

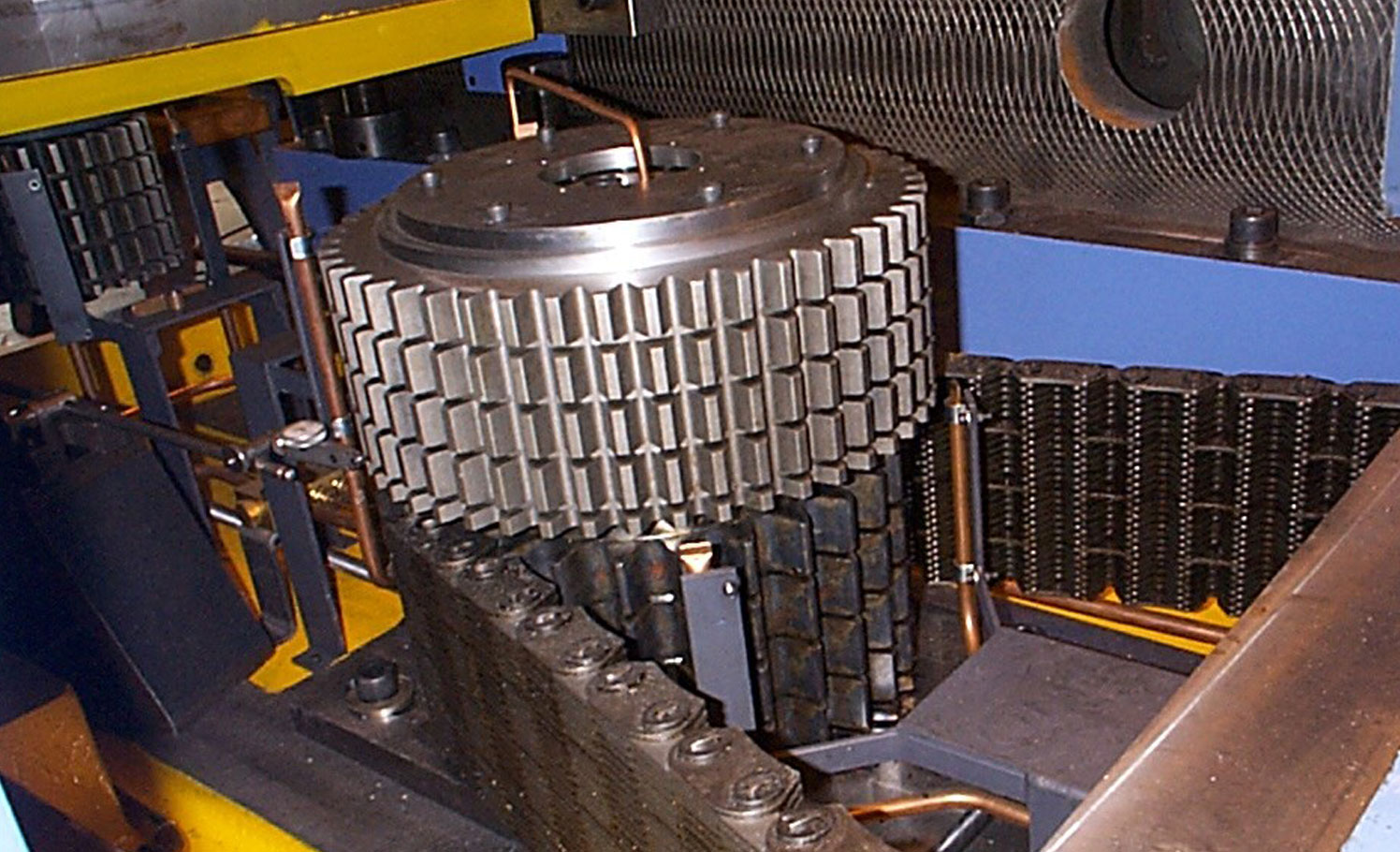

TWO 18 pocket AUTOMATIC TOOL CHANGERS. Each has following capacities

Maximum individual tool weight……………………………………………………………..… 55kgs

The weight on each ATC should be balanced and total should not exceed…656kgs

Maximum tool length (may vary according to final installation)………………. 650mm

Each pocket can be set up for either a turning tool or a live spindle tool or attachment

Other information

COOLANT | Capacity | 640 litres |

| Flow | 25 litres/minute |

| CONVEYOR | A powerful linear conveyor is supplied |

| ELECTRICAL SPEC | Voltage | 415 |

| KVA | 276 | |

| Frequency | 50Hz | |

| Phases | 3 + earth |

| WEIGHT | Machine structure excluding guarding, swarf conveyor and tooling | 52000kgs

|

SIEMENS 840D CNC Powerline

Since it’s introduction 840D has been regarded as the best CNC for complex machine tools.

Perfect for turning, milling, drilling and grinding on the Millennium

The system will be upgraded to continue to provide a very satisfactory performance.

We combine it with a new cabinet and new wiring, for maximum reliability performance

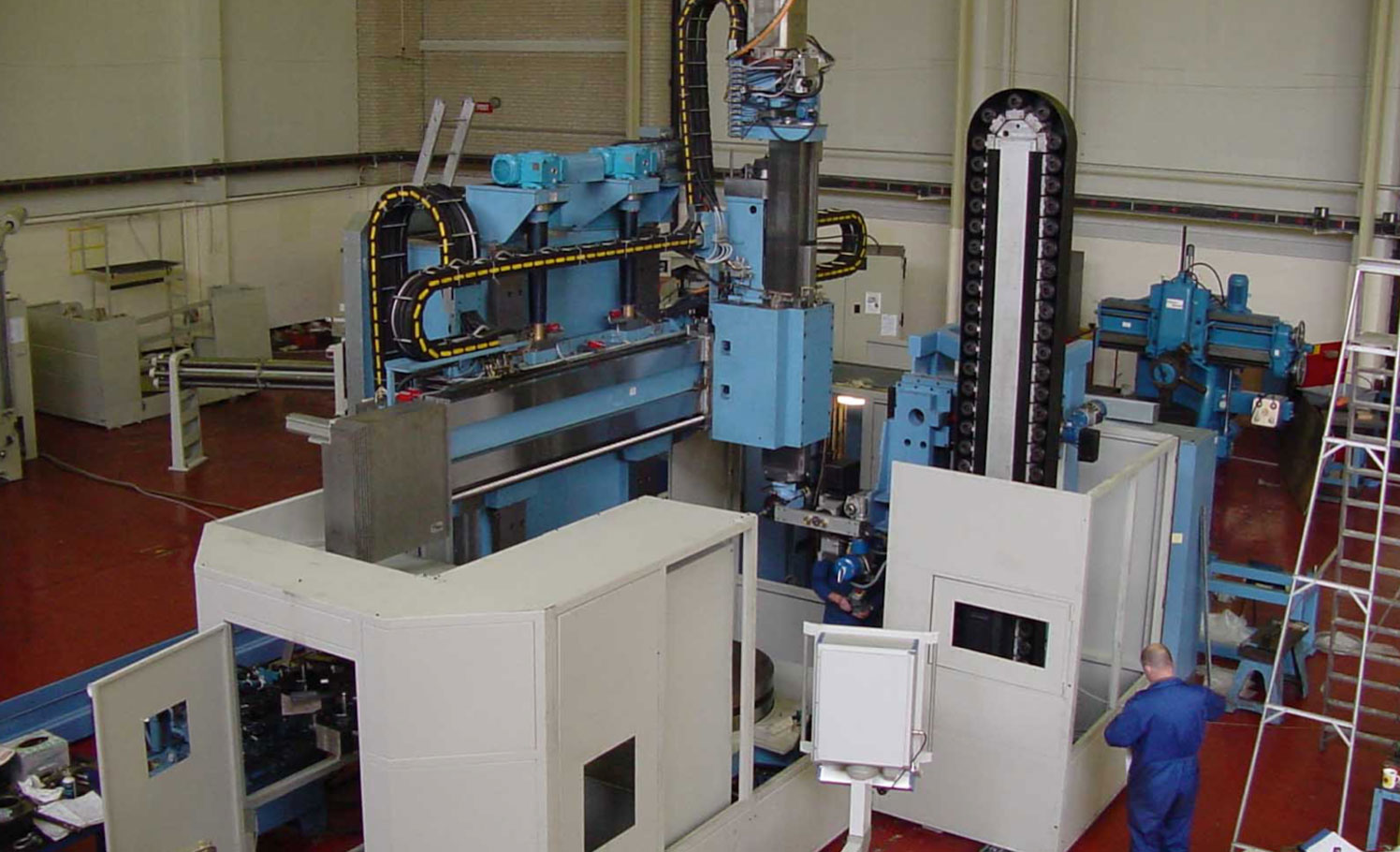

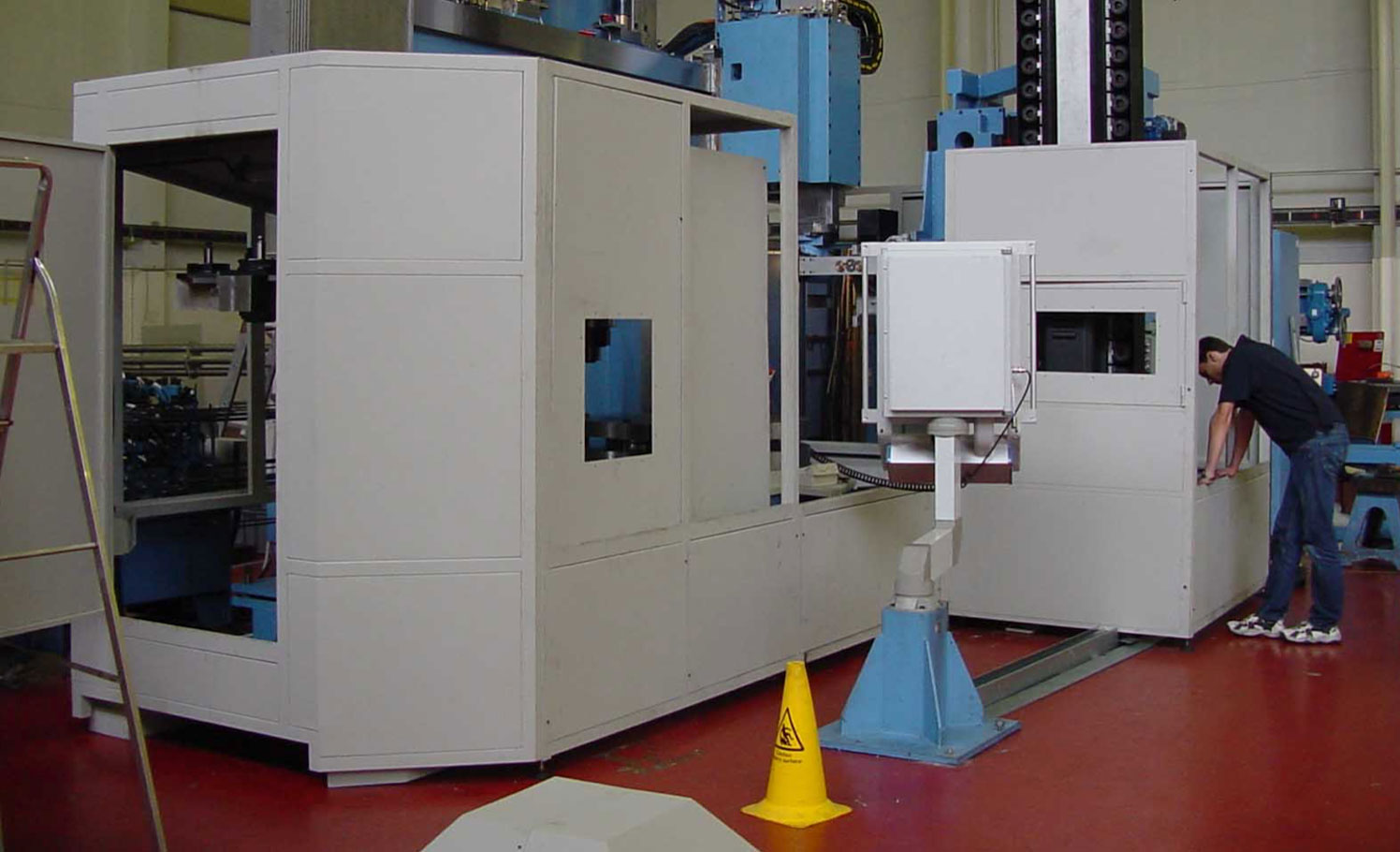

THE NEW GUARDS

The guard designs provide two options – i) standard style 3000mm high open top or ii) new design to totally cover the machine to protect contamination of the cutting zone and equally to prevent contamination of the working environment outside the machine. Photos below of similar guards taken during a recent installation

Benefits of ii) the total covering guards

Installation, commissioning and maintenance is made safer when working at height because we have engineers platforms built into the guard frame (see first guard photo below)

The door system is in two parts

The lower doors are the operators safety doors – full protection by the structure and interlocks The lighter upper doors require to be opened only when loading or unloading components

PRICING

For the machine refurbished and upgraded as outlined above and tested with full functions and operating tests in VTT, dismantled and loading to customers transport plus 12 months warranty if installed commissioned by VTT. Machinery Safety – Declaration of Conformity according to which country the machine is installed ……………………………………..………………………………………………………..£475,000.oo

Additions for guarding – option i) £40,000. option ii) £65,000

Transport, installation and commissioning

The method of transport will depend very much on the destination – 4 x 12m trailers or 40ft open top containers.

Installation onto a foundation prepared by others and commissioning can be budgeted at £40,000 plus travel and accommodation for 4 engineers